Robomouse Telemetry Project

by

Terry Smiley

Mechanical Engineering

Department

California Polytechnic State

University

San Luis Obispo

2000

Statement

of Disclaimer

Since

this project is a result of a class assignment, it has been graded and accepted

as fulfillment of the course requirements.

Acceptance does not imply technical accuracy or reliability. Any use of information in this report is

done at the risk of the user. These

risks may include failure of the device or infringement of patent or copyright

laws. California Polytechnic State

University at San Luis Obispo and its staff cannot be held liable for any use

or misuse of the project.

Table

of Contents

Section Page

Abstract 1

Introduction 2

Background/Noise 3

Dataflow 4

Programming 8

Robot

Construction 10

Procedure 13

Discussion

and Recommendation 14

Bibliography 16

Appendix

A.

Robosoccer: Rules and Information 18

B. Transmitter Wiring Diagram 19

C.

Receiver Wiring Diagram 20

D.

Schematics: MAX 233 and EDE 300 21

E.

Schematics: Ming TX-01 and Ming TX-99 22

F.

Schematics: Ming RE-99 and Ming RE-01 23

G.

Schematics: Parallax Stamp II 24

H.

Parts Information 25

I.

Transmitting Program 27

J.

Mobile Robot Program 29

Figures

Illustration Page

1. Radio Noise 3

2. Signal Waveform 3

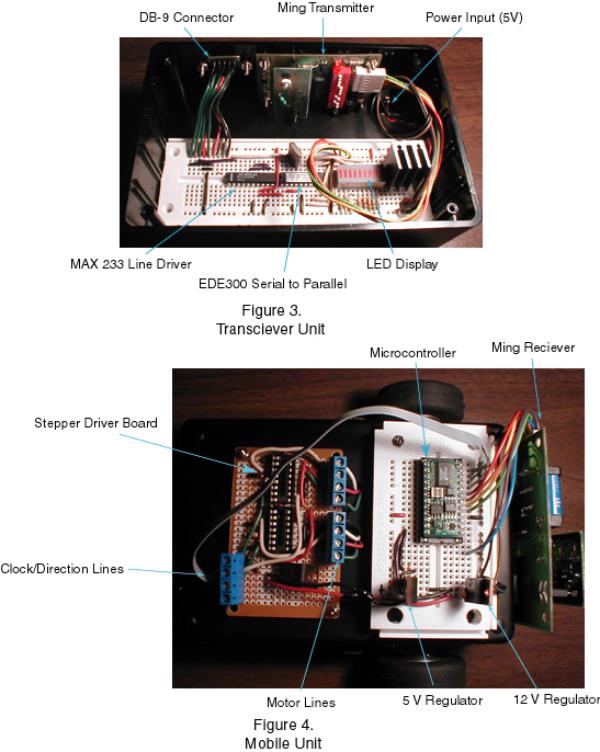

3. Transceiver Unit 5

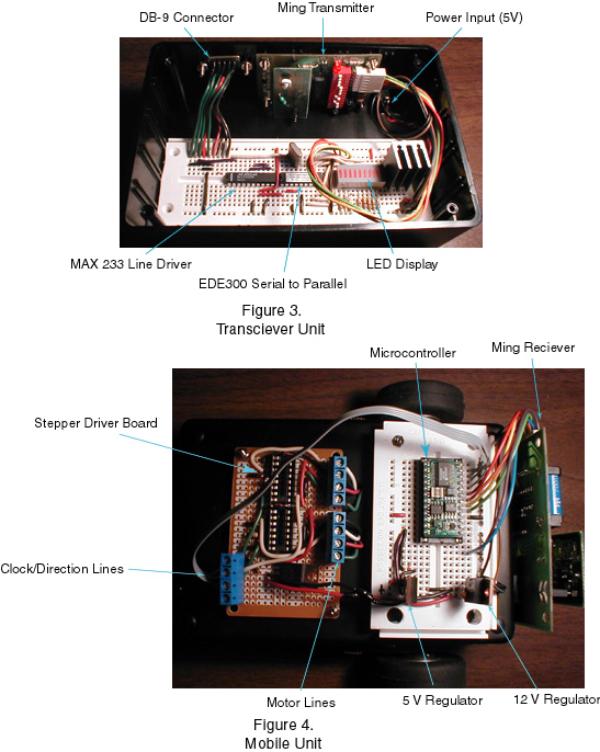

4. Mobile Unit 5

5. 1st View of Mobile Robot 11

6. 2nd View of Mobile Robot 11

Abstract

This

report outlines the design, construction and use of a simple 4 bit one way

wireless communication system between a DOS based personal computer (utilizing

the RS232 serial protocol) and a TTL level device (such as a mobile robot). In addition, specifications are given for a

proof-of-concept mobile robot. The

report includes wiring diagrams and sample programs in addition to the design

specifications and build procedures.

Introduction

The

object of this project was to design and build a simple, cost-effective

communication link between a personal computer (PC) and a small semi-autonomous

mobile robot (robomouse). This link

will transmit simple instructions to be carried out by the robot (forward, left,

right, etc.). The system was to be designed

to be compatible with a “robo-soccer” type event.

Robo-soccer

(also called robotic football) is a relatively new competition at different

international mechatronics/robotics conventions. The event consists of two teams of 3 robots each that play soccer

against each other with a golf ball on a ping pong sized field. The robots are monitored by an external

global vision system that then controls each of its robots via wireless links. For some sample rules and robots see

Appendix A, figures A1 and A2.

Building

a team of robots and the vision system to run them is a large task, but it can

be broken down into several smaller projects among different engineers. My goal

was to design and fabricate an inexpensive one way radio link between a

personal computer running DOS or Windows and one of the robots. Other engineers would concentrate on the

robots themselves, the vision system to monitor the robots, and the computer

program that makes strategic decisions and outputs the necessary data to my

radio link.

While

many wireless applications require two way data transfer, a two-way system is

unnecessary and expensive for certain processes. Although this design was developed with robo-soccer in mind,

there are many other practical uses for one way data communication. One of the most common uses is data

telemetry from a remote site to a computer (basically my system running

backwards). The remote site could be an

autonomous robot out collecting data, a race car on a closed track, or a

spacecraft sending back collected data.

Some

Background: Noise in Serial Radio Communication

While

wireless serial communication seems like a simple extension of wired serial

communication, it brings with it a host of new problems to be solved. Many of

these problems are based on the fact that low power radio signals have a

tendency to get distorted over time and space.

When

an AM radio transceiver sends an encoded signal it is modulating the amplitude

of the fixed frequency radio wave around a preset amplitude. The receiver can then look at the relative

highs and lows of the incoming radio waves (at the particular frequency) and

will determine whether it is a high or a low.

Problems arise when random noise in introduced to the radio wave and the

receiver cannot distinguish the noise from the real signal. A beneficial characteristic of this noise is

that in the 300 MHz range the noise tends to be in the form of upward spikes

during the low portion of the cycle, rather than downward spikes during the

high portion (see Figure 4 below).

Figure 1

Noise that may be introduced

into a radio signal

Because

of the nature of these upward noise spikes, we can reduce the error in our

system by maximizing the high portion of the signal. Figure 5 below shows an example of how an 8-bit data stream (with

a preamble) can be encoded to maximize the high time.

Figure 2

Maximizing the high portion

of an encoded signal

This

is just one way of reducing the error due to noise. Other ways include methods of error checking (such as a check-sum

system) or having the mobile application mirror the signal back to the base

comparison (requires two-way communication).

Flow of Information

This

project is all about getting information from one place to another. In order for this information to be sent

from the computer to the robot the data must be transformed several different

times. In this project the data goes

from the machine language of the PC to RS232 serial data to 4 bit parallel

data, where it is appended to an 8 bit address code. This 12 bit data is then serially sent by the encoder to the

transmitter where it is converted into a 300 MHz amplitude modulated

signal. This signal is received by the

receiver, converted to 12 bit parallel data (where the 8 bit address code is

verified), and then the 4 data bits are input into the microcontroller or

microprocessor as TTL level voltage.

The wiring diagrams for both sides of the systems (transmitting and

receiving) are located in Appendices B and C.

There is also a parts list with prices and ordering numbers located in

Appendix H.

Computer machine language to

RS232 (in computer)

With

this particular project I chose to use the C language because of its

simplicity. The program is set up to

output ASCI text to the COM1 port at particular times. The C program uses the BIOS library

functions to serially output this code in the RS232 form.

RS232 to serial TTL (in

“black box”)

Because

RS232 levels are 0 V and –13V they are not compatible with regular TTL level

chips (0V and 5V). Because of this, I

used a MAXIM Max233 RS232 receiver to

convert the signal into the standard TTL format. Please see the Max 233 pinout in Appendix D.

Serial TTL to parallel TTL

(in “black box”)

While

I could have transmitted the serial signal directly, I found that the error

checking functionality of the standard serial signals are not sufficient to

handle the noise inherent in low power wireless systems. Therefore I chose to utilize an exiting low

cost encoder/transmitter pair from Ming

Microsystemsä.

Because

the Ming system utilized parallel

input/output, I had to first transform my serial signal to a parallel one. To do this I used EDE300 Parallel/Serial

Transceiver IC from elabä (see figure D2, Appendix D for more

data). The elab IC took the TTL

level serial data and converted it into 8 bit parallel data, of which I used

the 4 least significant bits.

Parallel TTL to encoded

serial (in “black box”)

Early

in the project I had planned to encode the serial data using C and transmit

that over the radio signal, but this proved to be extremely difficult to do

with any consistency. Noise and error

checking are a large concern with radio signals, and with the nearby computer

the noise was even worse. The biggest

problem though, was the fact that if I were to do my own custom encoding then I

would have to write a complex routine to decode that signal, and this routine

would have to be carried out by the microprocessor on board the mobile

robot. While this is possible, the

robot’s processor is likely already going to be busy moving around or

collecting data, so a dedicated decoder is desired to free up that valuable

processing power. The Ming system is affordable and easy to

use, so it lent itself to this task (encoding and decoding, as well as the

radio transmission/reception).

Before

the encoder converts the 4 bit parallel input into a serial signal, it adds an

8 bit address to the beginning of the input.

This is a dip-switch set input that lets the encoder and decoder check

for errors. Next this 12 bit data goes

into the encoder. Because the Ming system utilizes a proprietary

encoding scheme I do not know the details, but it likely looks something like

the signal seen in Figure 5. This

signal could be determined with a high-speed oscilloscope but I felt that it

was beyond the scope of this project.

See figure E1, Appendix E for a wiring diagram of the encoder.

Encoded signal to 300 MHz AM

radio signal

The

transmission unit creates a 300MHz carrier signal that is broadcast throughout

the area as radio waves. Once the

analog circuit creates this signal it is modulated using the serial signal from

the encoder. This particular

transmitter uses amplitude modulation (AM), so the data signal is used to alter

the amplitude of the carrier signal. It

is the relative highs and lows in this modulated carrier signal that transmits

the data over the radio waves. See

figure E2, Appendix E for a circuit diagram of the transmitter.

300 MHz AM radio signal to

Encoded signal

Essentially

this is the reverse process of the transmitting routine. The receiver samples the radio waves in the

air and determines the relative highs and lows (amplitude) on the 300 MHz

frequency, sending them out as an encoded serial stream to the decoder. See figure F1, Appendix F1 for a circuit

diagram of the receiver.

Encoded signal to parallel

TTL

The

Ming system uses its own system for

decoding the encoded serial input. It

then checks the signal’s 8 bit address against its own 8 bit address (set with

dip-switches) to look for a match. If

these addresses do indeed match, the 4 bit data on the signal is output as

parallel TTL level data. This data can

then be used to control various actions.

See figure F2, Appendix F for a

wiring schematic of the decoder.

4 bit parallel TTL to microcontroller

Once

the 4 bit data is output from the decoder it is very easy to input into a

microcontroller or microprocessor. I

had originally planned to use a serial input into a microcontroller, but I felt

that by building the device to the specifics of say, the Motorola SCI

interface, I would be limiting the potential of the device. Instead, I chose to use simple 4 bit TTL

level data that can be input into a microcontroller port directly or through a

peripheral type system. Because of this

functionality, the radio link can be used on a Motorola 6802, a Motorola

6805, a Parallax Basic Stamp, or any

number of other microcontrollers/processors.

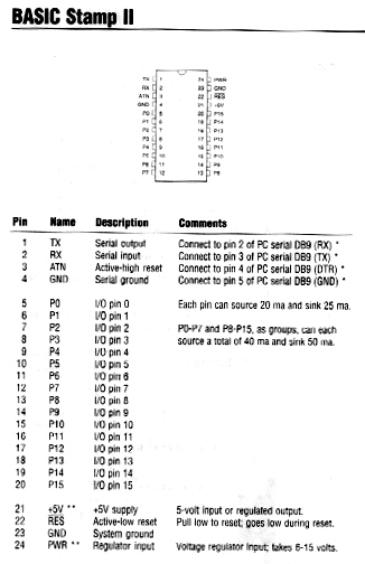

With my robot I chose to use the Basic Stamp II from Parallax. See Appendix G for a pinout of the Stamp.

Interpreting the 4 bit data

The

microcontroller/processor can deal with the incoming data in one of two

ways. The first method is for the

microcontroller to periodically poll the input lines, that is, check them

frequently, to see what signal lies there, and run the program

accordingly. Because my microcontroller

is very dependent on the input lines (it won’t run without the radio link), I

chose to utilize this method. The other

way to receive the data would be to have one of the data bits sent to the interrupt

request pin (IRQ or equivalent) on the microcontroller and have the interrupt

service routine check the radio input pins.

This would be a good solution to a remote application that only needs to

receive data intermittently and doesn’t want go through the time-consuming

process of polling the input bits.

Computer

Program (Transmitting side- PC)

The

computer program, written in Borland C, is designed to be a demonstration

program, and not really for use with an actual task. The program prompts the user for command information, speed

setting, and duration of motion, and then outputs these parameters to the COM1

port where they are sent to the mouse.

An annotated copy of the program is located in Appendix I.

A

more useful program would be tailored to meet the needs of the actual

problem. Such a program could take an

input data stream and output the data at different times. This would be ideal in the situation where

the input data stream came from a vision system or a joystick or some other

“real time” feedback device. The data

stream could also be produced from a .dxf drawing (like an AutoCAD drawing) of

a prescribed course. AutoCAD has

plotter outputs that could be converted (with yet another program) into an

appropriate data stream. With this

functionality an operator could load a drawing of the Mechatronics obstacle

course and the computer would be able to instruct the mouse on how to navigate

it.

The

program works like many simple DOS programs to take user input and modify it

into data that can be sent to the robot.

It does this by means of ASCII manipulation through if/then statements, while

and for loops, and the _bios_serialcom statement, which outputs

the data to COM1 (as it is set up). The

program also has a 3-digit time input, which sets the time that the command is

output to the robot. The program is

designed to run indefinitely, or to exit when the user types the letter q (for

quit). This program could be upgraded

to C++ with a windows environment fairly easily, but it is beyond my

programming skills at this point.

One

of the nice aspects of the PC/transmitter interface is that it is highly

portable. The transmitter attaches to

the PC via a DB-9 cable to the COM1 port on the PC and the transmit program can

run off of a floppy disk. Because the

transmitter unit incorporates serial to parallel conversion, no digital I/O

card is necessary on the host PC. I can

run this setup off of a cheap PC or a notebook computer without any additional

cost or set-up.

Computer

Program (receiving side)

The

receiver program is written in PBASIC and is designed to run on a Stamp II

microcontroller, but could easily be written for a Motorola or and Intel

chip. Because the radio data is coming

in on a 4 bit parallel bus, all we need to do is have the program poll the

input ports connected to this bus. The

program can then make logical decisions based on the state of this port. This setup can easily be used with a ME 405

micromouse running the Motorola 6802 processor.

I

chose to use the Stamp II microcontroller because of the fact that I could

program/debug the unit from the comfort of my home. The onboard EEPROM is sufficient to hold a simple program and the

processor is powerful enough to handle the simple tasks it is asked to

accomplish. The Stamp II is also very

well documented and can be used in a number of different situations.

My

program (located in Appendix J) first assigns variables based on the input bits

(from the radio link). First it

compares the first radio bit (on/off bit) to logic low and if they are equal it

stays at this location in the program, keeping the motors from running. If the first radio bit is high, the program

is allowed to proceed to the next step, where the speed is set to either high

or low. Next the two direction bits are

checked to see what direction we want to go.

Depending on these values (there are 4 combinations) the program

branches to a subroutine that actually pulses the motors in the correct

orientation for that motion. The speed

that is set at the beginning of the program is used in these subroutines to

pulse the motors for the right amount of time.

After the pulse has been sent to the motors the program returns to the

beginning to start all over again.

Because the program checks the radio bits continuously the

microcontroller is very quick to respond to changes in their status. You can be sure that the robot will not take

a single step in the wrong direction (pun intended).

Robot

Construction

The

mobile robot that carries the Basic Stamp II is made up of 5 basic

components. There is a frame,

motor/wheel assemblies, the motor driver board, the microcontroller board, and

the radio receiver. Below I will outline the functionality and basic design of

each of these parts. It is important to

remember that this robot was designed and built to be a proof of the radio

concept, and is therefore not necessarily the best design (it’s not!).

Frame:

The

basic frame is a simple project box from Radio Shack that has been heavily

modified to suit the task. I chose a

plastic box because I felt that the relatively low weight, the high stiffness,

and the low cost justified the decision.

The box has been inverted and the walls have been shortened with a

Dremel to save weight. Mounting holes

have been drilled and the back wall has been modified to accept a small rear

castor wheel. The frame could be made

significantly lighter (while maintaining stiffness) by drilling and shaving

unnecessary material away.

Motor/Wheel

assemblies:

With

this robot I chose to use a belt driven wheel assembly. The reason I did this was to get both drive

wheels on the same axis. The front axle

is fixed and the wheels are free to rotate about it. Attached to each drive wheel is a sprocket which mates to a

toothed belt. These belts mate to the

pinon gear that is press fit onto the stepper motors. The sprockets and belts were obtained from an old HP printer;

they were used with a DC motor to drive the print head back and forth over the

paper. The wheels were left over from

an old project, and are likely from a remote controlled airplane. Smaller, more precise wheels are an obvious

improvement. The motors are mounted to

the frame via 2-56 hardware.

Motor

driver board:

The

motor driver board was actually left over from my ME 405 project (although it

was never used). I constructed it based

on the circuit diagram provided by Dr. Yong on a piece of perfboard. Screw type terminals were added to

facilitate hookups. The board provides

a basic platform for two Motorola 3479 Stepper driver chips. Each of these chips receives two signals

from the microcontroller: a direction (CW or CCW) signal and a clock

signal. The chips automatically

sequence the output (motor) wires in the proper order, and keep track of the

current position of the motor. The

chips also provide power to the motors, so no external power transistors are

necessary.

Microcontroller

breadboard:

The

microcontroller breadboard serves two functions: providing a platform for the

mounting of the Parallax Basic Stamp II and regulating the power coming in from

the batteries. The platform for the

Stamp II is just a connection box for the inputs (the 4 radio signal lines) and

the outputs (the two sets of two motor control lines). The platform also makes the necessary power

and ground connections. The power

regulation section of the breadboard steps the 18 V input voltage down to two

voltages: twelve volt and five volt supplies.

The twelve volt power is used by the radio receiver and the motor driver

board, they require extra power to do their tasks. The five volt supply is used to power

the

microcontroller. The different supplies

share a common ground. The

microcontroller breadboard is mounted with 2-56 hardware.

Radio

receiver:

The

radio receiver is pretty well covered in the information flow section of the

paper. It is sufficient to say that it

receives the data from the modulated 300 MHz radio signal and then decodes and

outputs the data on a 4 bit parallel bus.

This 4 bit bus connects to the microcontroller breadboard. There are also power and ground lines that

connect to the voltage regulators, as well as a pair of lines that are

connected to a relay on the radio receiver.

This relay is closed whenever the radio receiver is in contact with the

transmitter, and can be used to stop a runaway mobile robot.

Procedure

to Operate Device

As

the system is currently constructed, the following steps should be taken to set

up all of the components:

The

transmitter (“black box”) needs to be plugged into its power supply. The supply should be 12 V DC, with the

positive pole on the inside of the plug.

The

transmitter should then be connected to a PC via COM1 and a DB-9 serial

cable. This is the smaller style of

cable with nine pins. If the computer

does not have COM1 available or there is not a DB-9 hookup, find the address of

a free serial port (using the computer’s BIOS settings) and rewrite that

portion of the software.

Once

the transmitter is hooked up, run the software off of a floppy or hard

disk. The program should be entitled

“radio.exe”. It can be run through DOS

or Windows.

Plug

the batteries into the robot. There

should be four 9V battery connectors and clips for these batteries.

The

program ought to prompt the user for an input.

The first input should be the type of motion desired. This will either be f (forward motion), b

(backward), l (left pivot), or r (right pivot).

The

program will now prompt the user for a speed.

There are currently only two choices, fast (f) and slow (s).

At

the next step the user is prompted to enter the duration of motion. This is a three digit number that

corresponds to hundredths of a second.

For example, entering 567 will yield a run time of 5.67 seconds. The divider (1/100) can easily be changed in

the software if longer periods are desired.

After

the three digit number has been entered, the user merely pushes enter and the

robot should run. The small green LED

on the outside of the transmitter should be lit during run time. Also, if the radio link is active (even when

the robot is stationary), the small green LED on the robot should be lit.

When

the motion has been completed, the program will prompt the user to hit another

character. When the user is done with

the program, “q” will quit the program, as will clicking the close button (in

Windows).

Discussion/Recommendation

When

this project was first conceived it was thought to be a part of a robo-soccer

competition, and it will still serve that purpose well. If the project were to be linked up to a

vision system (providing visual feedback) this could become a very powerful

platform. While robo-soccer is a great

way to introduce technology, it is not commercially viable and thus new

applications need to be explored.

One

possible avenue to explore is digital telemetry, the transfer of data from a

remote source back to the PC. To

convert this system to a data collector is very simple, it would require some

rewiring and wouldn’t be too difficult.

The data collector could be one of several types. It could be on a mobile platform, such as a

model rocket, a human powered vehicle, a model airplane, a kite; the list is

long. It could also be hooked up to a

fixed but remote system, such as a solar powered weather station, a volcanic

monitoring station, or a high mountain snow depth gage. All of these uses have the potential for

wireless digital communication, and they do not necessarily require high baud

rates. With an estimated one-time cost

of around 100 dollars this design is affordable enough to be used for small

developmental projects where high speeds and complex encryption are

unnecessary.

The

soccer-robot project could be extended through several other senior

projects. One project would be to design

and build the three small robots. They

should be compact and quick. The robots

could easily be controlled with a microcontroller, perhaps a Motorola 6805 or a

Stamp. The radio links would be my

system, with three different radio frequencies (transceivers and receivers are

available in different frequencies) all running a modified version of my

transceiver program on a single PC. I

would suggest DC servomotors for the drive wheels because of their high torque to

weight ratio. Rechargeable Ni-Cad batteries

(small radio control car batteries) would be a good choice for power.

Another

project would be to develop the vision system necessary to direct the cars in

the proper directions. The vision

system would not only have to recognize the three robots under its control, but

also the three opposing robots and the ball and the soccer playing field. This would be a rather complicated

undertaking, but there may be commercial software packages that would simplify

the process.

The

really challenging project will be the artificial intelligence needed to

interpret the data provided by the vision system and send the proper

instructions to the robots. This would

have to include strategic decision making as well as position and velocity

analysis. The robots need to know where

to go and how fast in order to keep the ball out of their goal and score on the

opposing goal. The software could also

be programmed to interpret the opposing team’s maneuvers and try to base the strategy

on the current situation. This is

obviously a large undertaking and would be suitable for a multi-person senior

project team, perhaps with computer science majors included.

As

challenging as this project sounds, I think that it would be a lot of fun and

everyone involved would learn a lot. It

is the sort of cutting edge design solution that Cal Poly is getting a

reputation for and should continue to pursue.

It would be really exciting if some day Cal Poly were able to compete in

this sort of competition on a national or international level, especially if

all of the work is done by undergraduate students.

Another

option is modify the competition so that it is simple enough to undertake as a

campus-wide competition, much like Robo-rodentia. Perhaps the Mechanical Engineering department could make such a

competition part of the ME 405 or 406 curriculum.

One

problem with these sort of senior projects (and senior projects in general) is

the high cost of construction. It would

be really helpful if there were more resources (I realize there are some) for

parts and money. Perhaps a mechatronics

“library” of motors, actuators, and chips that students could borrow from when

working on these types of projects. It

is possible to do this now, but it would help to have a list of available parts

to choose from.

Bibliography

Borland

C++: The Complete Reference. ©1997

McGraw-Hill.

From

BASIC (or FORTRAN) to C and a bit of C++:

Tutorial by W.M. Kays. (unpublished material)

M68HC05

Family- Understanding Small Microcontrollers- Rev. 2.0. ©1998 Motorola

Circuits,

Devices, and Systems- Fifth Ed. ©1992

John Wiley & Sons.

BASIC

Stamp Programming Manual- Version 1.9.

©1998 Parallax, Inc.

Sales/Technical

Support Manual- 315MHz RF Modules.

©1998 Parallax & DVP, Inc.

ME

405 Notes and Schematics: Y.C

Yong. (unpublished material)

Appendix

Appendix A. Robosoccer Rules and Information

Figure A1.

Rules for a

robo-soccer event

Figure A2.

An article on a robo-soccer

team.

Appendix D.

Schematics

Figure D1.

Pinout for EDE300

serial/parallel converter

Figure D2.

Pinout and schematic for

MAX233 RS-232 Receiver

Appendix E. Schematics

Figure E1.

Wiring diagram for TX 01

Encoder Motherboard

Figure E2.

Wiring diagram for TX 99

radio transceiver

Appendix F.

Schematics

Figure F1.

Wiring diagram for RE 99

radio receiver

Figure F2.

Wiring diagram for RE 01

decoder motherboard

Appendix G. Schematics

Figure G1.

Pinout for Parallax Basic

Stamp II

Appendix H. Parts List/Descriptions

(Sources and prices may not

exactly match built prototype)

Parallax Stamp II

Microcontroller

24 pins, Dual-In-Line package

$48.95 (Jameco Part No. 130892)

See

pinout page 24

E-Lab EDE300 Parallel/Serial

Transceiver

18

pins: Dual-In-Line package

$12.95

(Jameco Part No. 141541)

See

pinout figure D2 page 21

Ming Microsystems RE-99 RF

Receiver Board

5

v. operating voltage

$11.68

(Digikey Part No.RE-99V3-ND)

See

analog circuit figure F1 page 23

Ming Microsystems TX-99 RF

Transmitter Board

5

v. operating voltage

$10.00

(Digikey Part No. TX-99V3-ND)

See

analog circuit figure E2 page 22

Ming Microsystems TX-01 RF

Encoder Motherboard

12

v. operating voltage

$16.72

(Digikey Part No. TX-01-ND)

See

circuit diagram figure E1 page 22

Ming Microsystems RE-01 RF

Decoder Motherboard

12

v. operating voltage

$25.12

(Digikey Part No. RE-01-ND)

See

circuit diagram figure F2 page 23

Maxim MAX233 Multichannel

RS-232 Driver/Receiver

5

v. operating voltage

20

pins: Dual-In-Line package

$8.93

(Digikey Part No. MAX233EPP-ND)

See

pinout figure D1 page 21

DE-9 Connector (female)

$1.18

(Digikey Part No. A1001-ND)

DE-9

Cable (Male to Female)

$4.95

(Jameco Part No. 25700)

Experimentor 300 solderless

breadboard

$12.49

(Radio Shack)

10 Segment bar-type LED

$6.28

(Digikey Part No. P10723-ND)

4 MHz timing crystal

$0.94

(Digikey Part No. CTX006-ND)

Hook-up wire

22

gage solid (four colors)

$4.49

(Radio Shack)

Plastic Project Box (x2)

$4.39

(Radio Shack)

Various resistors (x3)

$0.49

(Radio Shack)

12 v, 500 mA wall-type power

supply

$12.99

(Radio Shack)

5 v voltage regulator

$1.49

(Radio Shack)

12 v voltage regulator

$1.49

(Radio Shack)

Assorted small hardware (x2)

$1.49

(Radio Shack)

Approximate

total cost: $200

This

total can be reduced by reusing many old parts. This price does not include the stepper motors, which were

obtained from Dr. Yong.

Jameco’s

phone number is 1-800-831-4242

Digikey’s

phone number is 1-800-344-4539

Radio

Shack is located at 209 Madonna Rd., SLO

Mid-State

Electronics is located at 1441 Monterey St., SLO

Appendix

I. Transmitting Code (C)

//This is a program designed to get

specific input from a user and//

//output the information in a 4 bit code

to COM1, where it will//

//be collected by an RF transmitter

connected to a mobile robot//

//Written by Terry Smiley in April 2000

for ME 462//

#include <stdio.h>

#include <conio.h>

#include <dos.h>

#include <bios.h>

int main(void)

{

char

com; //command code; forward, backward, left, right//

char

dat; //temp. variable used to collect data//

char

spd; //speed code; fast or slow//

char

out; //output character, combination of com/spd codes//

char

hsb; //hundreds bit, used to set delay value//

char

tsb; //tens bit, used to set delay value//

char

osb; //ones bit, used to set delay value//

int

dur; //duration of output signal, made up of hsb,tsb,osb//

long

int a;

char

e='e';

clrscr(); //clears

the screen//

bioscom(0,227,0); //initializes

port 0

while(1) //do while 1 is true (always; signifies infinite loop)//

{ //start of infinite loop (until q is pressed//

clrscr(); //reset

screen//

printf("Please

enter command (press q to quit)\n");

//prompt user//

printf("f...FORWARD\n"); //'menu' options//

printf("b...BACKWARD\n");

printf("r...RIGHT\n");

printf("l...LEFT\n");

dat=getch(); //get char. 'dat' from

keyboard//

if(dat=='q'){goto

end;} //exit program when q is

pressed//

com=dat; //set com equal to dat.//

printf("Please

enter speed\n"); //prompt user//

printf("f...FAST\n"); //'menu'

options//

printf("s...SLOW\n");

dat=getch(); //get char. 'dat' from

keyboard//

if(dat=='q'){goto

end;} //exit program when q is pressed//

spd=dat; //set spd equal to

dat.//

if(com=='b'

&& spd=='s'){out=8;} //check status of com,spd,//

//and

set com accordingly//

if(com=='r'

&& spd=='s'){out=9;}

if(com=='l'

&& spd=='s'){out=10;}

if(com=='f'

&& spd=='s'){out=11;}

if(com=='b'

&& spd=='f'){out=12;}

if(com=='r'

&& spd=='f'){out=13;}

if(com=='l'

&& spd=='f'){out=14;}

if(com=='f'

&& spd=='f'){out=15;}

putch(out); //display character 'out'//

printf("Enter

duration of motion + cr (1/10sec; 3 digit number)\n"); //prompt user//

hsb=getche(); //set hsb to first number

inputted into keyboard//

//display

hsb//

tsb=getche(); //set tsb to second number

input into keyboard//

//display

tsb//

osb=getche(); //set osb to third number

input into keyboard// //display

osb//

getch(); //wait for cr (or any

key)//

dur=((hsb-48)*100)+((tsb-48)*10)+((osb-48)*1); //set

dur. to weighted variable// //proportional

to input value//

_bios_serialcom(1,

0, out); //send 'out' to COM1//

for(a=0;

a<10;++a){ //delay routine with quick exit

(hopefully)//

delay(dur); //pauses for ‘dur’ milliseconds//

}

_bios_serialcom(1,

0, 0); //send 00 to COM1//

printf("\nProcedure

completed: any key to continue\n");

//prompt user//

getch(); //pause until keystroke//

} //end

of infinite loop//

end: //label for quit function//

_bios_serialcom(1,

0, 0); //resets COM1//

return

0;

} //end of main

program//

Appendix J. Mobile Robot Code (PBASIC)

'This is a program written in PBASIC by

Terry Smiley; 4/23/2000

'This program is designed to accept 4 bit

radio data and run two stepper motors ‘accordingly

input 0 'bit

0 of radio data

input 1 'bit

0 of radio data

input 8 'bit

0 of radio data

input 9 'bit

0 of radio data

output 4 ‘motor

1 pulse bit

output 5 ‘motor

2 pulse bit

output 10 ‘motor

1 direction bit

output 7 ‘motor

2 direction bit

'various

initializations

code var word ‘these

variables are used

code0 var code.bit0 ‘throughout

the program

code1 var code.bit1

code2 var code.bit2

code3 var code.bit3

delay var byte

start 'start

of infinite loop

code0=IN0 ‘get values from radio

input lines

code1=IN1

code2=IN8

code3=IN9

if

code0=0 then start 'check

for on/off pin

if

code1=1 then fast 'check

fast/slow pin

delay=30 'set slow speed

goto

direction ‘skip fast

setting

fast

delay=15 'set fast speed

direction

if

code2=0 and code3=0 then backward ‘radio

input lines determine

if

code2=1 and code3=1 then forward ‘motor

directions

if

code2=1 and code3=0 then left

if

code2=0 and code3=1 then right

forward

high

10 ‘sets

motor directions

high

7 ‘sets motor

directions

high

4 'pulse clock

high

5 'pulse clock

pause

delay ‘pause

determines speed

low

4 'pulse

clock

low

5 'pulse

clock

pause

delay ‘pause

determines speed

goto

start ‘back

to beginning

backward

low

10 ‘sets motor

directions

low

7 ‘sets

motor directions

high

4 'pulse clock

high

5 'pulse clock

pause

delay ‘pause

determines speed

low

4 'pulse

clock

low

5 'pulse

clock

pause

delay ‘pause

determines speed

goto

start ‘back

to beginning

left

high

10 ‘sets

motor directions

low

7 ‘sets

motor directions

high

4 'pulse clock

high

5 'pulse clock

pause

delay ‘pause

determines speed

low

4 'pulse

clock

low

5 'pulse

clock

pause

delay ‘pause

determines speed

goto

start ‘back

to beginning

right

low

10 ‘sets motor

directions

high

7 ‘sets motor

directions

high

4 'pulse clock

high

5 'pulse clock

pause

delay ‘pause

determines speed

low

4 'pulse

clock

low

5 'pulse

clock

pause

delay ‘pause

determines speed

goto

start ‘back

to beginning

end ‘end

of program